Solid Diffuser Aerosol Inlet

Short Name or Variable Name

SDI

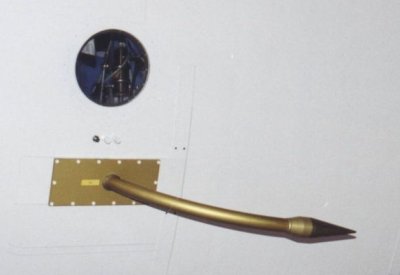

- The Solid Diffuser Inlet (SDI) is an air sample inlet for aerosol instruments located in the cabin of the C-130. It is a clone of the University of Hawaii SDI that was designed to create isokinetic flow conditions at the inlet tip to minimize loss of aerosol particles during passage from the atmosphere into the aircraft cabin for sampling. It is a forward-facing diffuser inlet with a relatively sharp tip. Suction is provided by a blower inside the aircraft, and flow is kept isokinetic (velocity at the inlet tip equals flight speed) by a flow controller. The controller also provides a measurement of the total volume flow and pressure. Six diffuser cones are available, with inlet diameters of 4.4, 5.4, and 5.9 mm (unshrouded), and 5.4, 6.35, and 7.75 mm (shrouded)

- The photo above shows the SDI inlet mounted on right side of C-130 fuselage, providing air samples to several instruments inside the aircraft. Inlet points into the direction of flight.

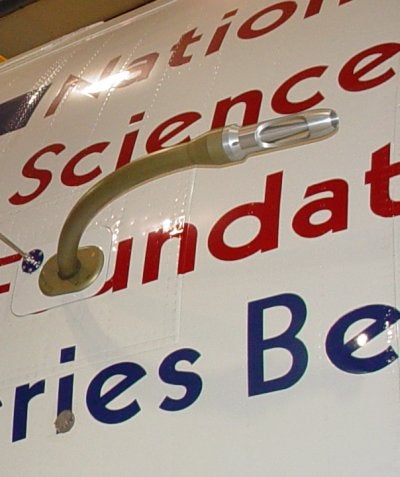

- The variation of the SDI shown above has a flow alignment shroud. The Clarke inlet was developed by Tony Clarke (Univ Hawaii) and a copy was made for the C-130. For more information, see documentation link at right.

- The hole at the inlet tip is ~5 mm ID and the diffusing cone expands to 38 mm in order to reduce the average velocity by a factor ~60. The cone half-angle is only 4.4 deg, which prevents internal flow separation and recirculations.

- Edges of the tip are precision machined to have an elliptical cross section. This shape reduces the tendency that knife-edge inlets have for flow separation when the flow is not aligned with the inlet axis.

Lead Contact

Mike Reeves