Counter-flow Virtual Impactor inlet

CVI General Information

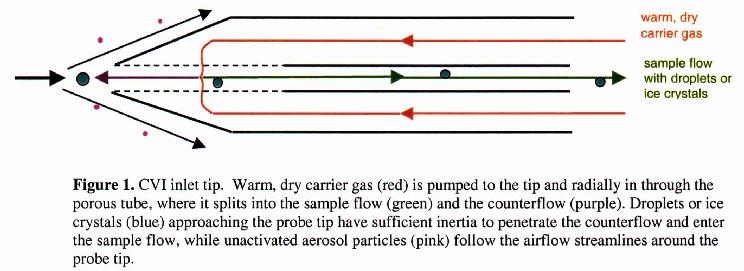

The NCAR counterflow virtual impactor (CVI) (Noone et al., 1988; Twohy et al., 1997) is an airborne instrument that can be used for studies of aerosol/cloud interactions, cloud physics, and climate. At the CVI inlet tip (Figure 1), cloud droplets or ice crystals larger than about 8 µm aerodynamic diameter are separated from the interstitial aerosol and impacted into dry nitrogen gas. This separation is possible via a counterflow stream of nitrogen out the CVI tip, which assures that only larger particles (cloud droplets or ice crystals) are sampled. Cloud particles larger than the "cut-size" are injected into dry carrier gas flow (usually N2) where they evaporate. Because droplets or crystals in a sampling volume of about 200 l/min are impacted into a sample stream of approximately 10 l/min, concentrations within the CVI are significantly enhanced. The water vapor and non-volatile residual nuclei remaining after droplet evaporation are sampled downstream of the inlet with selected instruments. These may include a Lyman-alpha or similar hygrometer, a condensation nucleus counter, an optical particle counter, filters for chemical analyses, or user instruments.

A variety of instruments can be fed from the CVI, and they monitor characteristics of the evaporated cloud residuals. CVI is anti-ice heated and suitable for supercooled liquid water clouds. System uses heated tubing, fittings to divide the sample, and flow control for the cut-size. RAF operates two independent CVI systems that are specially designed for the GV or C-130. These systems have been used on NASA DC-8 and UND Citation-II.

Measurements Provided: Depends on the choice of instruments that are fed by CVI. May include cloud particle concentration, condensate mass, water vapor (for isotopic analysis) and aerosol particle residuals.

Measurement Characteristics:

- Overall estimate of uncertainty: depends on downstream instrument characteristics

- Response time: ~1 to 3 sec, depending on flow rates

- Precision:

- Other measurement characteristics (comments on signal/noise, bias limits, etc): Susceptible to contamination when cloud particles hit the tip and break into fragments. May exhibit long hysteres is times when passing through high watercontent clouds.

History of Significant Changes: Stainless steel tip and piping were replaced with Titanium to address concerns about contamination when SS was ablated by high speeds and cloud particle impaction.

Temperature and pressure RAF standards. Gas flow uses Gilibrator. Water vapor is TDL absorption, referenced to RAF standard.