Forward Scattering Spectrometer Probe, Model 100

This instrument is described in RAF Bulletin 24 and the original user manuals for the instrument. Some of that information is repeated here. This instrument was introduced in about 1976 and remained the standard instrument for measurements of cloud droplet size distributions for about 30 years before some significant improvements and changes in optical characteristics were introduced in newer probes. The current versions are sometimes called model SPP-100 instruments after the revised signal-processing package provided by Droplet Measurement Technologies, Inc. The primary difference is fast-response electronic components that make it possible to operate the instrument at higher airspeeds, although not at GV airspeeds. The instrument uses a focused beam from a He-Ne laser and detects light scattered from that beam by cloud droplets. Electronic and optical components define a sample volume centered in the probe aperture and use scattered light pulses to count and size individual cloud droplets.

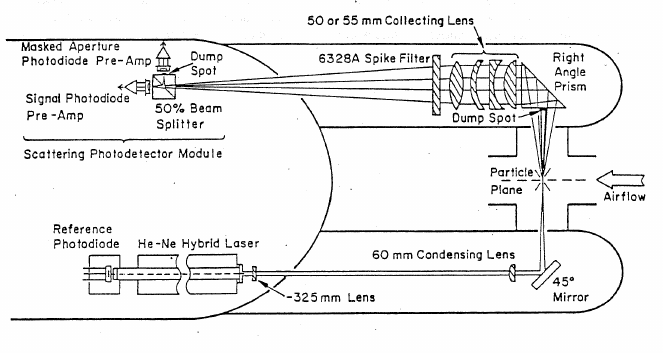

The optical components are shown in the following schematic diagram:

The beam diameter at the focal point (shown as the "particle plane" in the diagram) is about 0.2 mm. After that, light not scattered from the beam strikes a dump spot on the collecting optics and is not seen by the detection circuitry. The optical components then focus scattered light at angles of about 5-13 degrees from the original beam onto a photodiode where the magnitude of the scattered light is measured. To define the sample volume along the beam to a small region near the focal point, a beam splitter splits the collected signal into two parts and one part is directed onto a second detector in front of which a mask is placed to determine the quality of the focus at that location. If the image is poorly focused, a significant part of the signal bypasses the dump spot and is detected, while if the particle is centered in the focal plane and therefore produces a focused image then the masked detector sees no signal. The two signals (from the main photodiode and the masked photodiode) are then compared, and if the latter exceeds a fixed percentage of the former then the pulse is rejected as being outside the depth-of-field of the instrument. An additional restriction on the sample volume is imposed by accepting only pulses with widths that exceed the average width measured. This eliminates short-duration pulses arising from passage through the edges of the beam, and so reduces the sample area further (typically to about 62% of the beam diameter). In the original FSSP, an additional correction was made on the basis of an estimate of how much dead time was associated with processing particles, a measurement called the "activity". In the SPP version, this has been replaced by a direct measurement (named "oflow") of how many light pulses above threshold are not detected because the probe is processing other particles.

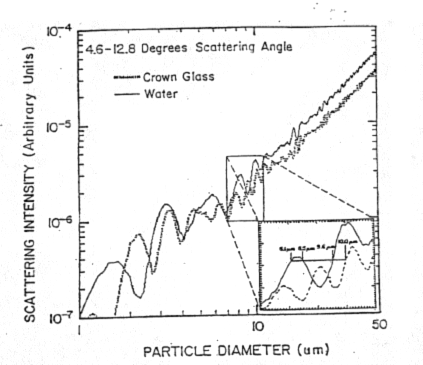

The following figure shows how the intensity of scattered light varies with the diameter of the scattering sphere. Results for glass as well as for water are shown because glass beads are often used for calibration of the instrument and such calibration results must then be converted to an equivalent calibration for water. For diameters below about 10 micrometers, there are regions of ambiguity where a unique assignment of size to a particular scattering intensity is not possible, so bin assignments for the probe are often defined to avoid such ambiguity. The resulting pulses are then sized into 15 bins, with sizes that can vary depending on the operating mode of the instrument but typically have bin sizes of 3, 2, 1, or 0.5 micrometers depending on the range selected (respectively range 0, 1, 2, or 3). In range 0, the nominal size range is 2-47 micrometers.

Expected scattering signal vs diameter of water or glass spheres

The calibration is checked and adjusted if necessary by using glass beads and requiring the modal concentration produced by different-size beads to lie in the bin expected on the basis of Mie calculations.