Buck CR-2 Cryogenic Hygrometer

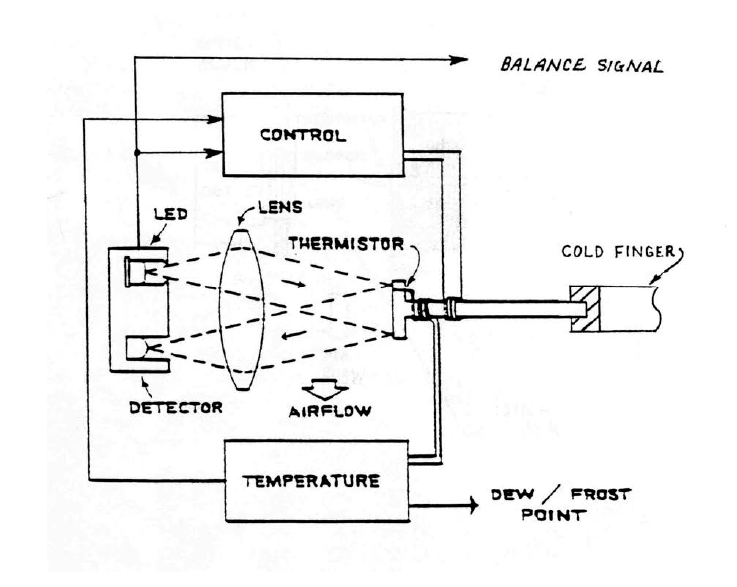

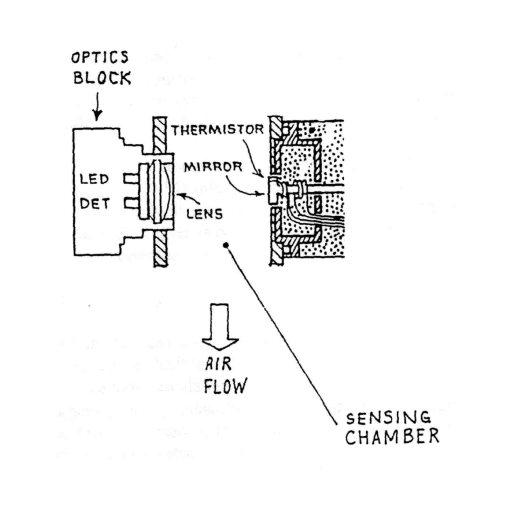

- The CR-2 hygrometer determines the frost point of the air in its internal chamber by cooling a mirror until frost appears on the mirror and then maintaining the mirror at the threshold temperature for such frost to be present. A Stirling-cycle cryocooler is used so no cryogen escapes to the atmosphere. Optical sensors detect the presence of frost on the mirror, as illustrated in the diagrams below, and a platinum RTD sensor in thermal contact with the mirror is used to measure the mirror temperature. Pressure is also measured in the sensing chamber so the frost point can be converted to other measures of humidity like mixing ratio. This is essential to obtaining useful measurements because lines from an inlet and to an exhaust port are used to maintain flow through the instrument, so the pressure in the internal chamber usually differs from the ambient pressure at the flight level. When the measurements are used, the frost-point measurement in the chamber is converted to various measures of humidity at the ambient pressure outside the aircraft. There is a Users' Manual (referenced in the Documentation section at the end of this page) that describes the instrument in some detail and provides the operating characteristics from which the following entries were derived.

Model: CR-2

Measurements Provided: Dew point inside the instrument, along with pressure and housekeeping information

Typical Sampling Rates: 1 Hz

History of Significant Changes: The instrument was first flown for testing on the C-130 in 2011, and will be flown again in 2013 on the GV as part of the IDEAS project. These test programs are for initial testing of the performance of the instrument and for deciding if this should be an instrument routinely operated and supported for users. An initial implementation of software code was installed in 2011 and is described in the Technical Note on Processing Algorithms.

The primary calibration is that of the temperature sensor used to determine the temperature of the mirror on which frost forms. This is performed by the manufacturer and is traceable to NIST calibrations. The pressure transducer in the housing also affects the derived measurements, but the results are relatively insensitive to uncertainty in this measurement.