Since the 1960s, NCAR’s Earth Observing Laboratory (EOL) has successfully managed numerous instrument developments and field projects. Each is different and requires a specific set of skills, expertise, planning, and instrumentation. Likewise, instrument development has been an integral part of EOL’s mission for decades and is an important way in which the laboratory supports the scientific community. Such a culture of innovation fosters a plethora of ideas and inventions. How are these ideas taken from the minds and notebooks of scientists and engineers and made into reality? EOL’s Design and Fabrication Services (DFS) plays a major part in this process.

DFS’ expertise lies in four areas. Its mechanical design engineering services design, analyze, and develop creative and original work used to manufacture a wide variety of instruments for a surprisingly diverse set of customers (more on that later). Their fabrication services use computer-aided manufacturing (CAM) to create custom and unique instruments from many different types of materials, including aircraft-grade aluminum, titanium, stainless steel, and engineered polymers. Perhaps least known, DFS’ logistics support performs several different functions, including certified crane operation for all of NCAR (even for international field projects), packing and shipping instruments/materials for field campaigns, surveying for and setting up the S-Pol radar, painting, and equipment repair. Lastly, DFS also provides procurement services, meaning that they manage all material stock, certifications, and job estimates as efficiently as possible. Procurement specialist, Brad Foote, handles all procurement, shipping, and outside services for all projects within DFS. “Brad’s expertise in locating and ordering flight hardware and materials enables DFS engineers to concentrate on the design knowing Brad will have the parts ready in time to meet their customer’s schedule,” said Facility Manager Jim Ranson.

DFS’ expertise lies in four areas. Its mechanical design engineering services design, analyze, and develop creative and original work used to manufacture a wide variety of instruments for a surprisingly diverse set of customers (more on that later). Their fabrication services use computer-aided manufacturing (CAM) to create custom and unique instruments from many different types of materials, including aircraft-grade aluminum, titanium, stainless steel, and engineered polymers. Perhaps least known, DFS’ logistics support performs several different functions, including certified crane operation for all of NCAR (even for international field projects), packing and shipping instruments/materials for field campaigns, surveying for and setting up the S-Pol radar, painting, and equipment repair. Lastly, DFS also provides procurement services, meaning that they manage all material stock, certifications, and job estimates as efficiently as possible. Procurement specialist, Brad Foote, handles all procurement, shipping, and outside services for all projects within DFS. “Brad’s expertise in locating and ordering flight hardware and materials enables DFS engineers to concentrate on the design knowing Brad will have the parts ready in time to meet their customer’s schedule,” said Facility Manager Jim Ranson.

Not only is DFS partially responsible for cementing EOL as a hotbed of atmospheric science innovation, but those in the facility are able to offer their services to other laboratories within NCAR and also the atmospheric science community, as long as the funding originates from the National Science Foundation or another government agency in support of scientific research. Below are some examples of the instruments and setups DFS has fabricated, manufactured, and/or designed for EOL, NCAR, and the atmospheric science community.

EOL:

- The entire S-Pol radar setup, except the antenna

- The Laser Air Motion Sensor (LAMS)

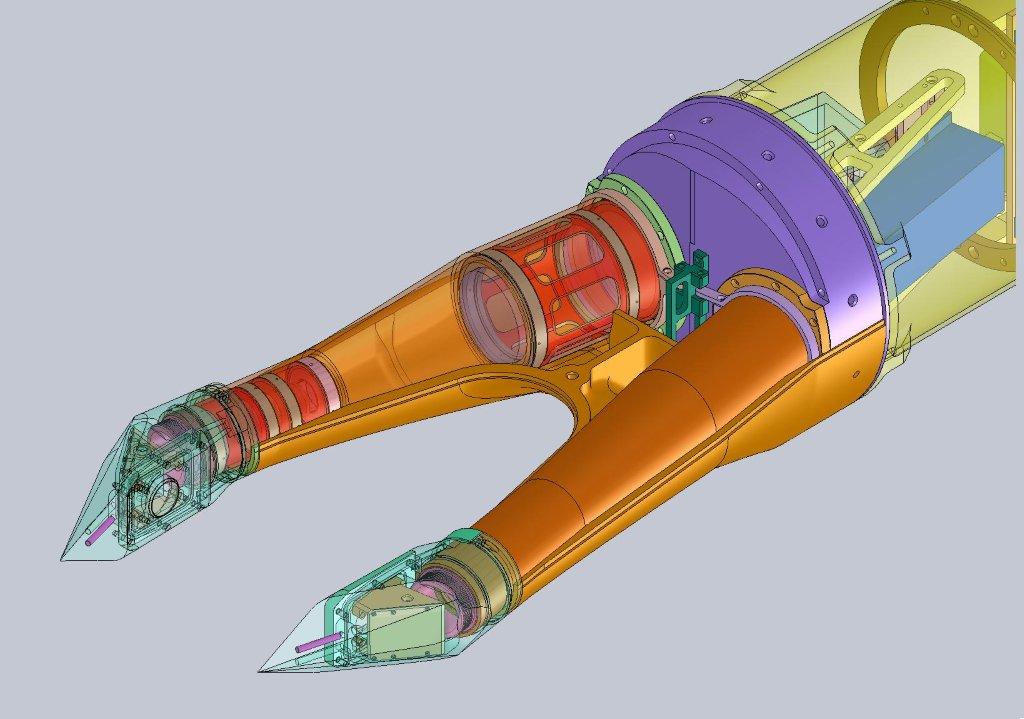

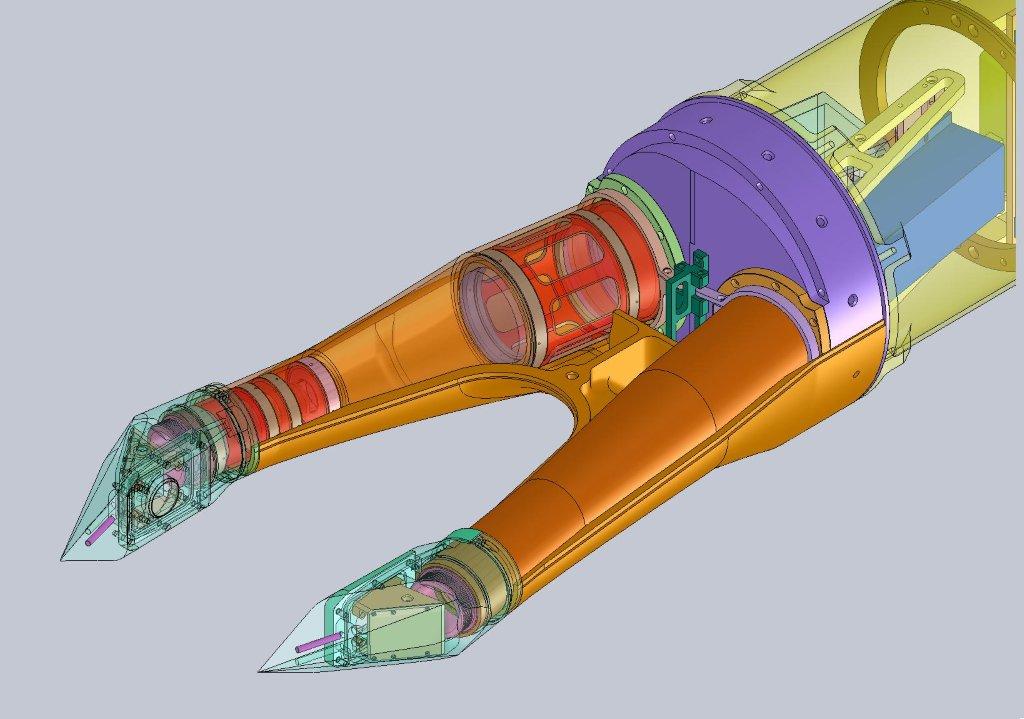

- HIAPER Cloud Radar (HCR)

- NSF/NCAR GV AVAPS® dropsonde system

- Water Vapor Differential Absorption Lidar (WV DIAL)

- Holographic Detector for Clouds (HOLODEC)

- HIMIL inlets

NCAR:

- Solar tracker for ACOM

- X-pol mount system trailer for RAL

- Sunrise gondola for HAO (original build and rebuild)

- A microburst demonstration exhibit for UCAR’s Mesa Lab

- Video ice particle sampler MMM

Community:

Lidar beam steering units for the Army and NIST

Lidar beam steering units for the Army and NIST- Vertical Cavity Laser Hygrometer (VCSEL) for Princeton University

- Parabolic and flat reflectors for Colorado State University (CSU)

- Gulfstream 550 wing stores for the German Aerospace Center (DLR)

- HIMIL aircraft inlets for NASA

- GlobalHawk Dropsonde system for NOAA

- Ice nucleation chambers for CSU

Many in the atmospheric science community look to DFS for mechanical engineering, design, and fabrication because of the expertise of those in the facility. One of those experts is machine shop supervisor, Karl Schwenz. He has worked in DFS for 17 years, so he understands the abilities of those in the facitiliy and the instrument design process. He said the staff at DFS is what sets them apart. “We have a pretty amazing crew,” said Schwenz. “The most unique thing about DFS is the instrument makers’ ability to have input on the outcome of a project.” Since the instrument makers have been working on atmospheric science instruments for so long, they have the ability to suggest changes to their customers to save them time and money. They understand what they are building and the context of the instrument’s use. “Empowerment is a wonderful thing, and we do that here,” said Schwenz.

DFS has the ability to perform end-to-end design and fabrication for many projects that are funded by the National Science Foundation. For more information about the facility or to request they build something for your project, please see their webpage or contact Jim Ranson.